BEST Lab

Battery | Energy | Semiconductor Technology

電池 | 能源 | 半導體科技

Recent News

Focus

Our research group focuses on developing next-generation energy systems enabled by semiconductor materials and technologies. We aim to reduce dependence on fossil fuels, enhance energy efficiency, improve energy storage performance, and minimize both production costs and environmental impact. Through innovative science and engineering, we strive to create practical solutions that harmonize technological convenience with long-term sustainability.

本研究室致力於運用半導體材料與技術,開發次世代能源系統。我們的研究目標包括降低對化石燃料的依賴、提升能源使用效率、強化儲能性能,同時減少製程成本與環境污染。透過創新科學與工程技術,我們希望在追求科技便利的同時,也實現永續發展的願景。

Rechargeable High-Energy-Density EV Battery

The rapid advancement of electric vehicles and portable electronics has driven a growing demand for efficient rechargeable batteries. However, current technologies still fall short of meeting real-world energy requirements. Developing energy storage systems with high energy density and superior performance has therefore become a critical focus. While lithium-ion batteries remain the dominant technology, their energy density is fundamentally limited by electrode materials. To overcome this, we are actively exploring advanced materials such as silicon, silicon oxide, high-performance lithium titanate, and lithium metal anodes, along with lithium-sulfur, sodium-ion, and potassium-ion batteries, as well as novel cell architectures. These innovations are expected to play a vital role in next-generation battery development.

隨著電動車技術與可攜式電子產品的迅速發展,對高效能可充式電池的需求持續攀升。然而,現有電池技術尚難以完全滿足實際應用需求,因此,發展具備高能量密度與優異性能的儲能系統成為當前關鍵課題。鋰離子電池雖為目前最成熟且廣泛應用的技術,但其能量密度仍受限於電極材料的瓶頸。為突破此限制,我們積極投入開發新型材料,如矽、矽氧化物、高性能鋰鈦氧、鋰金屬等負極材料,以及鋰硫電池、鈉/鉀離子電池與創新電池架構,這些技術有望大幅提升未來電池的整體效能與儲能密度。

Redox Flow Cells

Redox flow batteries are a class of rechargeable energy storage systems that utilize dissolved active species in liquid electrolytes. The total energy storage capacity is determined by the size of the external electrolyte tanks, making these systems highly scalable and well-suited for applications such as smart grids and stationary renewable energy storage. Flow batteries offer unique advantages, including modular design, long cycle life, and enhanced operational safety. However, several challenges remain, such as electrode degradation, crossover of active species between compartments, and the need to reduce manufacturing and system-level costs to achieve commercial viability.

液流電池是一種使用溶解態活性物質作為能量載體的可充式電池,其儲能容量主要取決於外部電解液槽的體積。因此,其可靈活調整儲能規模,特別適合應用於智慧電網與大型再生能源的定點儲能系統。相較於其他儲能技術,液流電池具有系統模組化、高安全性與長壽命等優勢。然而,目前仍面臨諸多挑戰,包括電極材料劣化、正負極物質交叉污染,以及製程規模化所帶來的成本壓力。

Alkali Metal Ion Implantation Techniques

The implantation of alkali metal ions—lithium, sodium, and potassium—has emerged as a critical technique in the development of next-generation energy storage materials. By incorporating these ions into host structures via physical or chemical methods, this approach enables compensation for initial Coulombic inefficiencies, while also tuning the structural, electronic, and ionic transport properties of the material. It is particularly relevant for anode materials such as silicon, silicon oxide, and metal oxides, and can be integrated with solid-state electrolytes or high-energy-density battery systems. Future research will focus on improving the uniformity of ion distribution, enhancing interfacial stability, and scaling the process for practical electrode manufacturing.

鹼金屬離子(鋰、鈉、鉀)的精準佈植技術,正逐漸成為次世代電池材料設計中的關鍵策略。透過物理或化學方式將鋰、鈉或鉀離子有效地嵌入主體材料中,不僅能預先補償首次循環損失(ICE),亦可調控材料結構、電子性質與離子傳導行為。此技術廣泛應用於矽、矽氧化物、金屬氧化物等負極材料,並可與固態電解質或高能量密度系統整合。未來的研究將著重於提升離子佈植的均勻性、反應界面的穩定性,以及在大型電極製程中的可行性。

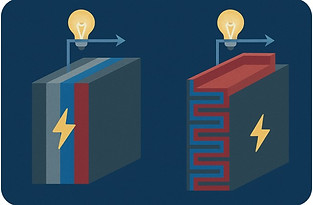

Thin-Film & 3D Battery

With advances in semiconductor fabrication, thin-film batteries can now be seamlessly integrated into integrated circuits, where a single pair of thin anode and cathode layers is sufficient to power microelectronic devices. Their ultra-short ion transport paths offer a distinct advantage in enabling fast charging. For applications requiring higher energy density, 3D battery architectures allow for increased active material loading while retaining excellent rate performance. Precision manufacturing techniques ensure high yield, superior performance, and efficient material utilization in 3D battery production.

隨著半導體製程技術的成熟,薄膜電池已可無縫整合至積體電路中,僅需一對薄膜正負極,即可為微型電子裝置提供自有電力。其薄型電極結構大幅縮短離子傳導距離,展現出極佳的快速充電能力。針對需要更高能量密度的應用,三維立體電池可藉由增加活性材料載量,同時維持優異的倍率性能。透過高精度製造工藝,3D電池能實現高良率、高性能與極高的材料使用效率。

Graphene-Based Design and Applications

Graphene is a two-dimensional material consisting of carbon atoms arranged in a hexagonal lattice via strong in-plane covalent bonds. It is widely recognized as the thinnest, strongest, and most conductive material known. By selecting appropriate graphene precursors and synthesis strategies, a wide range of graphene-based architectures—such as core–shell, composite, ultralight porous, and layered structures—can be achieved. Furthermore, tailored processing methods enable uniform dispersion of graphene, even in water- or heat-sensitive systems, expanding its applicability across energy storage, electronics, and advanced material platforms.

石墨烯是一種由碳原子透過平面共價鍵組成的二維六角晶格結構,擁有目前已知最薄、機械強度最高、導電與導熱性能最佳的材料特性。藉由設計合適的前驅體與合成策略,可製備出多種石墨烯衍生結構,例如核殼型、複合型、低密度高孔隙型與層狀結構等。不同製程方式亦可實現石墨烯於水敏與熱敏材料中的高均勻分散與穩定結合,使其廣泛應用於能源、電子與材料工程等領域。

Battery Recycling and Rare Metal Recovery

With the growing adoption of lithium batteries in electric vehicles and energy storage systems, the environmental and resource challenges posed by end-of-life batteries have become increasingly critical. Advanced recycling technologies aim to efficiently recover valuable metals such as lithium, cobalt, and nickel from spent batteries, enabling their reintegration into new battery materials through eco-friendly processing. Current methods include physical separation, pyrolysis, hydrometallurgy, and emerging techniques like bioleaching. Research continues to evolve toward low-energy, low-emission, and high-purity recovery processes. Future directions focus on full-pack recycling, direct regeneration of electrode materials, and the development of sustainable recycling systems integrated with renewable energy sources.

隨著鋰電池在電動車與儲能系統中的廣泛應用,報廢電池所帶來的環境衝擊與資源浪費問題日益受到重視。回收技術的核心在於從使用後的電池中有效回收鋰、鈷、鎳等關鍵金屬,並透過綠色製程將其重新利用於新一代電池材料。常見策略包括物理分選、熱解法、水冶法與生物冶金等,並持續朝向低能耗、低污染、高純度分離與高價值再利用目標發展。未來技術亦將聚焦於全電池模組級回收、材料直接再製程以及與再生能源整合的永續回收系統建構。